In the industrial sector, reliable and efficient fluid handling systems are essential for various processes. Whether you're working in cosmetics, the right pumping solution can make a world of difference. This is where Ace Lobe Pumps step in, offering unmatched performance, versatility, and durability for industries that require precise fluid transfer. Acelobe Pump, established in 2003, has become a trusted name in the world of lobe pumps. With over two decades of experience, Acelobe Pump specializes in manufacturing high-quality rotary lobe pumps designed for both sanitary and industrial applications. Their dedication to quality, customer satisfaction, and innovation has earned them a reputation as one of the leading manufacturers in the global market. In this article, we will explore the different types of lobe pumps, the benefits of using Ace Lobe Pumps, and how these pumps are transforming fluid handling across multiple industries.

The Basics of Lobe Pumps

A lobe pump is a type of positive displacement pump commonly used to transfer fluids in various industries. It works by trapping the fluid between two or more lobes, which rotate in a series of interlocking actions. This design allows lobe pumps to provide consistent and efficient fluid flow with minimal pulsation, making them ideal for handling sensitive or high-viscosity liquids. The primary advantage of lobe pumps is their ability to move a wide range of fluids, from thin, watery liquids to thick, viscous substances. This versatility makes them a go-to choice for applications in cosmetics. Unlike other pumps, lobe pumps are designed to gently handle liquids, ensuring that the product's integrity remains intact. This is particularly important when dealing with delicate ingredients, such as those used in food and cosmetic products.

The Advantages of Using Ace Lobe Pumps

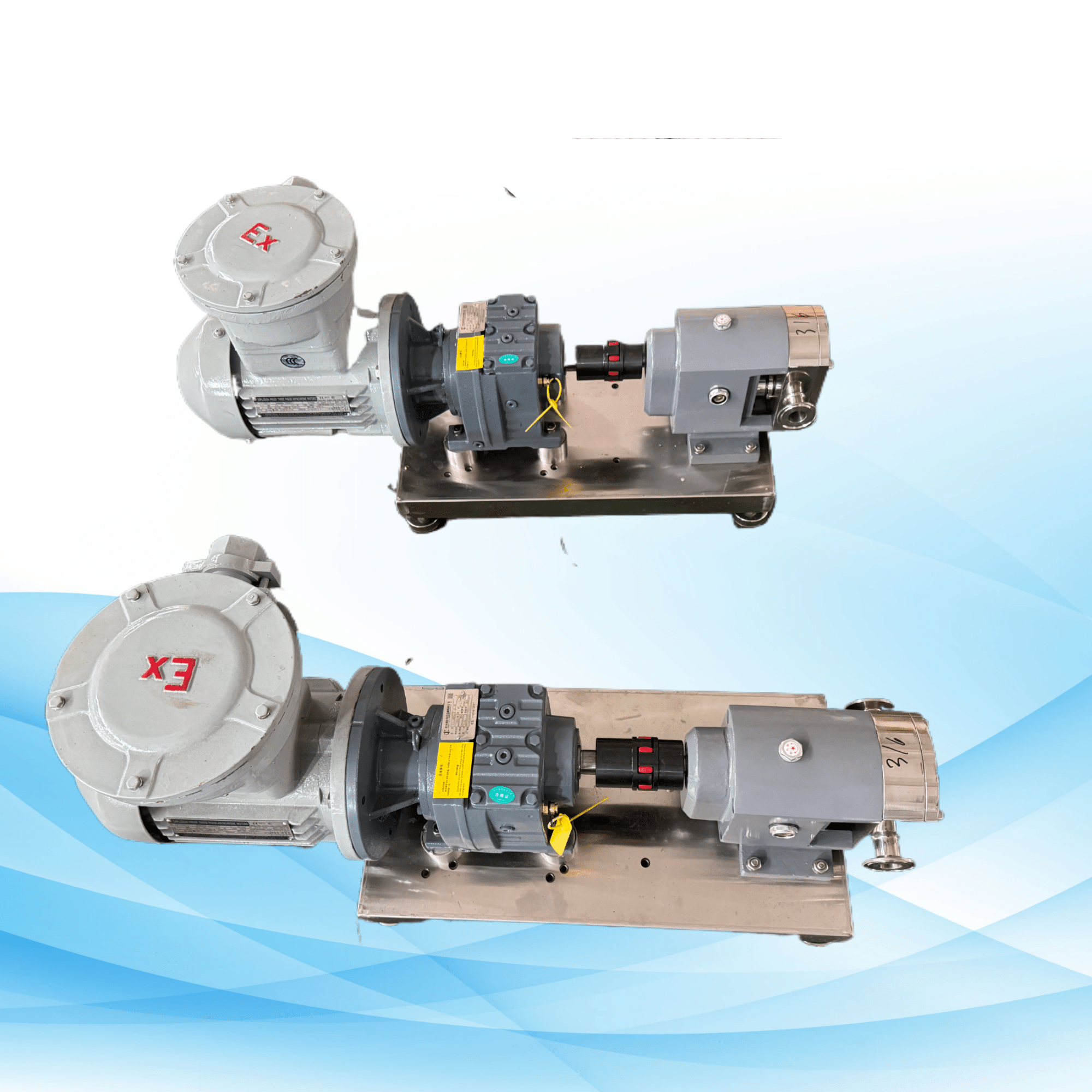

One of the standout features of Ace Lobe Pumps is their precision engineering. These pumps are built with a strong focus on durability and longevity. Manufactured from high-quality 316L/304 stainless steel, Ace Lobe Pumps are resistant to corrosion, ensuring that they can handle even the harshest working environments. This makes them perfect for industries that require hygienic and reliable solutions. The precision engineering of lobe pumps allows them to provide a consistent flow rate, reducing the risk of product wastage or inefficiency in the production line. With Ace Lobe Pumps, you can count on precise, continuous fluid handling, whether you're working with low or high-viscosity liquids. Acelobe Pump’s product range is designed to cater to a wide variety of industries, including cosmetics. The lobe pump designs can handle a broad spectrum of fluids, such as oils, syrups, creams, pastes, and even hazardous liquids. This versatility makes Ace Lobe Pumps suitable for various applications, including food industry processes where they manage ingredients, dairy, oils, syrups, and sauces, pharmaceutical applications for transferring delicate formulations, ointments, and creams, cosmetics processes like transferring lotions, shampoos, and conditioners, and chemical industries that rely on the transfer of abrasive, corrosive, or high-viscosity liquids. Each Ace Lobe Pump is designed with customizable features to meet the specific needs of your application. Whether you're handling a high-viscosity paste or a thin liquid, there's a lobe pump that suits your needs.

One of the reasons why Acelobe Pump has gained such a strong reputation in the industry is its commitment to performance. Ace Lobe Pumps are known for their exceptional efficiency, providing consistent flow rates with minimal maintenance. This translates into lower operational costs and more reliable processes for businesses. The pumps are available with flow rates up to 100 m³/h, allowing them to lobe pumps handle both small and large-scale operations. Their low pulsation and smooth flow characteristics help improve process control, making them ideal for applications that require precise and reliable fluid transfer. For industries like cosmetics, maintaining hygienic standards is essential. Ace Lobe Pumps are specifically designed to meet these high standards. Their sanitary design ensures that the pumps do not contaminate the product during transfer. The smooth internal surfaces prevent the accumulation of product residue, which is critical for maintaining hygiene in sensitive environments. This makes Ace Lobe Pumps particularly well-suited for lobe pumps industries where cleanliness and compliance with health regulations are a top priority.

Building the Best: The Technology Behind Ace Lobe Pumps

At the heart of every Ace Lobe Pump is its high-quality craftsmanship, engineered with precision to meet the toughest industry demands. The pumps are manufactured using premium materials, ensuring that they can withstand the stresses of heavy-duty operations while maintaining their efficiency and reliability. Acelobe Pump's focus on quality control and meticulous design guarantees that each lobe pump performs optimally under varying pressures, temperatures, and fluid types. The use of 316L/304 stainless steel not only enhances the longevity of the pumps but also ensures that they remain resistant to corrosion, making them ideal for use in sanitary environments. This level of engineering excellence is evident in every aspect of the Ace Lobe Pumps, from their compact design to their high-performance capabilities. Whether you're operating in harsh conditions or dealing with challenging fluids, Ace Lobe Pumps ensure that your operations run smoothly and efficiently.

The Future of Fluid Handling: Ace Lobe Pumps

As the demand for efficient and precise fluid handling solutions continues to grow across various sectors, Ace Lobe Pumps stand out as a game-changer. Their combination of durability, precision, and efficiency makes them the preferred choice for businesses seeking to optimize their fluid transfer processes. By delivering consistent performance, low maintenance requirements, and versatility across different applications, Ace Lobe Pumps are helping industries achieve higher productivity, lower operational costs, and better overall results. The innovative design and focus on hygienic standards ensure that Ace Lobe Pumps are a top choice for industries where product quality and safety are paramount. From the food industry to pharmaceuticals, cosmetics, and chemicals, Ace Lobe Pumps are leading the way in revolutionizing fluid handling technology. Their impact on the market is undeniable, as they continue to provide businesses with reliable and cost-effective solutions for a wide range of fluid transfer needs.